Updated 01/13/16

Rebuild

What I plan to

achieve here is the documented rebuilding of two old 1969

Chrysler marine 383 engines. Well, one at a time anyway. We'll

start with #1 portside. What you will see in the pages to follow

is my attempt at doing it the right way. But understand this, it

will be my way, and not necessarily be the right or safe way.

What follows is a story only. Not a rebuild manual! So sit back

and read on. Without having to get your hands dirty, you too may

learn a thing or two. My only hope is that it will help someone

in the future in a similar situation or give some light on what

is to come. Thanks for coming! Send me mail. Mike Wolfe. wolfman@inreach.com

A rebuild can be

a daunting project. I myself have never rebuilt a large boat or

auto engine. I've done my fair share of water pumps, starters,

carburetors and the like. I started working on engines when I was

a young man. Starting small with 2- and 5-horse Briggs and

Stratton lawn mowers with my dad. Moving up to rebuilding dirt

bike motorcycle engines with my dad, then to larger faster street

bikes (without my dad). Then time went by and I & my

soon-to-be wife worked on our 550 Jet ski together.

After the Jet ski was a fun one, a 1942 Mercury

Super 5 outboard. Completely restored after being found

buried in the dirt in a farmer's barn.

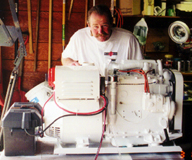

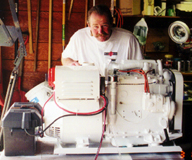

Lastly

was the 6.5 kw Kohler gen set project. (See Kohler

power plant)It

came with the boat and it was shot and in pieces.

|

Looks

like a show room model.

(The

genset not me!)

|

So now what do I

do? Where do I start? You call the friend who knows Mopar. Get a

good book on it, and ask around. Then you extrapolate all the

information provided and make a game plan and stick to it.

Mistakes can be very costly and must be avoided. One wrong

component or procedure can cause a catastrophic failure and a

total loss to your rebuild. I shall move forward slowly.

One of the most

important things in the successful rebuild of a broken engine is

to do a proper post mortem during the disassembly stage. We want

to find a complete and sure reason why this engine failed.

Collect any and all evidence that you can find as you take things

apart. Don't be in a hurry to go scrapping and cleaning right

away. Stop and take the time to look close at the gasket seals.

Look close for derbies or chunks of ??? or burn marks. Talk over

what you find with your gear head buddy's or machine shop guy.

Enjoy this part of the job! If you don't catch the reason it quit

working, it may get past you on the Reassembly and you will have

done all for not!

Get Stuff Ready

Engine Stand:

It's time to

find a good used "Hemi type" engine stand. One that can

handle the big blocks completely loaded up and not sag or bounce

too much. I will be needing one for some time due to the fact

that once this engine is done I will have #2 engine to do. So

renting a stand would be out of the question. Also, when all this

is over, I could, at my leisure, build a third engine up as a hot

standby. (maybe not, we'll see) Thanks to good buddies like Dr.

Don, (Hi Don!), who heard my cry for help, I now have the use of

his Snap-on engine stand. All he wanted in return was a trip on

the boat. He said it was 10 years old and has seen only two other

projects. He said his wife said "Use it or lose it, I'm

tired of stepping over the damn thing!" It now has a new and

useful home... : )

Chain Hoist:

Pat brought me

an old, heavy and crusty 1/2 ton chain hoist/wench. This big old

"Yale" unit was caked with years of ??? crud, and

barely worked and it was heavier than hell! But it did work.

However, before I could trust such a unit on my engine, it needed

to come apart for inspection, cleaning, and testing.

I'm glad to say

that it cleaned up nicely and still seemingly works. Made a

big-ass mess, too. Now I need to clean and inspect every link of

chain. Yes. Every single one! Then I'll want to load test it...

How?

In the end I

found a sale at "Harbor Freight" and got a brand new

"one ton" (2000lbs.) unit. It had twice the load capacity

in half the size. $50. "Not bad" I think I'll feel safer using the new one.

Cherry Picker:

This is a dilemma.

The engine is in a hole. The safe but expensive way to extract

this engine is to take the boat out of the water (risk) and use a

big forklift using a long boom to ease it out. I'll bet at least

5 Boat dollars before it would be over.

(One "Boat

dollar" = One hundred you and me dollars)

My plan to date is

to dismantle the engine piece by piece in place, all the way down

to the short block. This would take a 1,300 pound mammoth down to

a plus or minus 400 pound "Pain in the ass." Daryl

tells me that 4 men, by hand could get it out and in the truck

easily. I don't think so. If one were to drop the engine in the

bottom of the boat it could easily put a big hole in it and we

don't want that now do we? I'll probably get a cherry picker on

board some how.

At the same Harbor

Freight sale, I got a new two ton shop crane ($189.) Normally

$240. Man is it cool! (orange color) I just love this stuff. I

had to take a picture after a fresh coat and wipe down of WD-40.

(To remove the shipping grease and finger prints.) By the time my

wife got home I was in her parking spot, crane fully extended

fifteen feet in the air, hanging from the top my 200 pound

freestanding shop vice with the new shiny chain hoist. There I

was frozen in the headlight beams like a deer in the middle of

the road. I was busted! New tools.

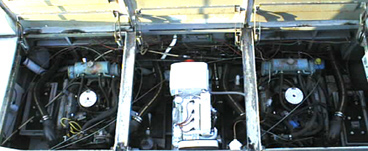

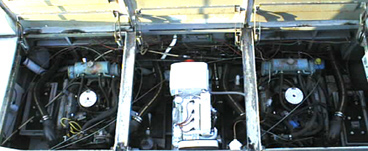

The old engines as

they sat.

#2 Engine.

(

Starboard)

Model

M383.BDL16/274

Serial

number E032920

PN 4/22

Runs.

Ticks, Smokes. Power steering unit works.

Barely

useable.

|

#3 Engine

KOHLER

electric plant

Model 6.5A23 (50226D7)

Ser#

312398 Kohler

Controller

# C-245479

KW 6.5 /

cycles 60 Volts 120 / RPM 1800

AMP/TERM

54.2 / Batt volts 12

Newly

rebuilt last year (1999)

|

#1 Engine.

(Port Side)

Model

M383/BDL16/274

Serial

number E032919

PN- 4/22

Runs, No

oil pressure. not froze) Bad tick sound. smoking right

bank.

Not

useable.

Coming

out now

|

Paragon

Gear works (Transmission)

Taunton

Mass.

Model

PD31-L

Serial

number SM-7101

|

Note that

on both engines and transmissions the serial numbers are

sequential.

|

Paragon

Gear works (Transmission)

Taunton

Mass.

Model

PD31-L

Serial

number SM-7100

|

It begins.

Some people can

do a wham-bam-thank-you-ma'am rebuild. No nonsense, get it apart,

get it fixed - get it built - get it in and get it on down the

river. This is not necessarily a bad thing...after all, the

engine does belong in a boat and not on the bench. However, to

proceed in this fashion you must have all the cash ready and then

you have to trust the guy that does all the work.

To me the boat

engine is the number two most important thing next to the hull.

If there is any question of its ability fire up and get you and

your loved ones home safely, you can never hope to be able to

relax and enjoy the boat for its original purpose.

My game plan

will somewhat differ. I can't say this enough times. "If you

treat the Refit project as a job, you will soon start to resent

the whole thing and end up hating the whole damn thing."

After, of course, emptying your bank account. Then having to sell

out, if you're lucky.

We are going to

keep the light-hearted, slow-going way of doing it. No rush. We

are going to have a good time on this new, not-so-easy project

and treat it as the hobby that it is. Concentrate on the task at

hand. One step at a time. When stumped, or lost on something,

sleep on it for a day or two. Roll it around in your head for

awhile. The answer will come to you. If you still can't come up

with the answer in a reasonable amount of time, ask a

"Mopar" wizard. Then you can proceed to the next step

on the list with a clear mind.

Call me weird

but I like to talk to the spirit in my engines as I work. It's

all part of the relaxation thing. I speak to them in a calm

positive manner, as would a doctor talk to his sick and worried

patient. "Now this may pinch a bit," or like a family

pet, "come on baby, open up, let daddy see." Never use

a cross tone or foul language at them. They don't like that and

can cause serious and costly complications.

: )

Before you

start.

Before you even

pick up wrench or screwdriver, the first tool you need to pick up

is a pencil. Draw pictures of the lay out. The hoses - from's and

to's. The same thing with the electrical connections.

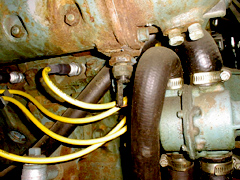

This is

#2. From here you can see the many hoses, wires and

cables that need to be recorded and removed.

|

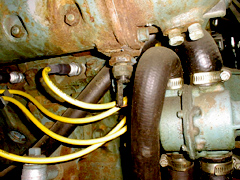

Some

places where my eye's can't fit to see I stuck the camera

in to have a closer look.

|

I also had the

use of a friend's data camera and took a good number of pictures

around the block, top and bottom for further reference.

Keep in mind, as

I found out later on, the way things are installed now is not

nesacaraly the way things are sapost to be???

Switched off all

the battery selection switches and disconnected the power, ground

first, and removed the batteries, close all the sea cocks and

turned the fuel off. I also removed all the coolant and engine

oil.

Now, time to

remove all the bolted on engine parts that can get in the way.

Pumps, pulleys, starter. The carburetor too. Anything that may be

in the way of a clean and lighter extraction.

In the mean time...

It's time to

clean of the work bench and put away all last year's stuff and

the tools from an in-between project. Wipe down all the wrenches

and replace a light bulb or two. Make room for some flat spots

for all the engine parts we will be bringing home. I have to

review, replace, or whip back into shape all the external bolt-on

components of the engine. Here's what I'm doing while I have

everything apart. "Record all your part numbers!" Write

them all down, each and every part that has a designator on it.

Measure things as well, pulley sizes and casting numbers, cable

lengths, all of it! Some parts have manufacturer names and

numbers all over them. Write them all down. This will help you

big time in the long run. When you need that certain part you

won't have to stand on your head to find the numbers or help you

on your way to obtaining spares. "Knowing the right part

number is directly related to getting the right part, the first

time. Especially if you are doing mail order parts" (First

time? That's a joke!)

Sea water pump:

Cool sea water

enters the boat via a through hull fitting/valve known as a

"seacock." Once in the boat the water passes though a

strainer unit with a clear service port to see if the screen

needs cleaning. This filters out most all of the larger stuff

that can foul the cooling system. Water then travels up and

enters this "Sea water pump" It's job is to charge the

one large line to the "Heat exchanger" with cool river

water. Cool water moves through the heat exchanger in a

criss-cross kind of way and collects what else? Heat from the

coolant that circulates on the inside of the engine block system!

Coming out of the heat exchanger from two smaller ports to flow

to the exhaust manifold elbows and then discharged out of the

boat from there.

This little pump

sure looks nice right after a bead blast job! I'm not sure if

it's brass or bronze or even a mix of the two. I do know that the

surface will turn a nice green color if left unprotected or

uncovered for long. I may not paint it. I did however paint the

cast iron pulley, it will rust quickly after bead blasting. This

pump was rebuilt with a kit last year before we moved the boat

for the first time. No more then three hours were added to the

engine's overall time since then. Looking in the end of the pump

with a flashlight I can see all the impellers still have new

shiny looking edges as I turn the pump over. All the blades were

there. Good, we don't want to go back in there if we don't need

too. I also did a quick check for end play by grabbing the pulley

and pushing in and out on the shaft. Nice and tight. No excess

play or slop. Post mortem. Nothing wrong found in this pump short

of running less efitionently causing the engine to run at higher

than normel temperature. So up on the shelf with it! Next to all

the other finished stuff. "Next"

Heat exchanger:

What a weird

beast! It's a neat part though. It stands up on top of the engine

looking all cool. What surprised me was the amount of busted pump

rubber inside this sucker. If you are a user of this type of

cooling system and never have had the ends off of your heat

exchanger, run, don't walk to your boat and go inspect it now!

One bolt on each side, one large rubberized gasket. A good

maintenance port for the future! With the amount of stuff I found

in this unit it must have restricted 40-50 percent of the total

water flow.

This unit is a

good looking piece of equipment. All the in's and out's all made

up of copper, brass, all soldered up. When you clean it all away

it's a real beauty! One other big point of interest, on either

side of the exchanger, tapped into the primary "sea

water" chambers are "zinc pencil inserts" These

must be pulled and inspected! Mine were so far gone I had to go

and look up on the internet just to see what they were!!! (Zinc

inserts to protect and add life to the engine and its parts.)

This heat

exchanger was a pleasure to do bench work on. With the caps off I

back-flushed the unit with the hose. More rubber parts and a

lot more stuff found. Then I capped all the holes and put some

mild solvent in it and let it stand for awhile. After a thorough

flushing and some drip drying we were ready to proceed. I made a

small wood stand to support the unit and keep it from rolling

around and hurting itself. The custom copper hose flanges are

soft and have been bent here and there. Using a small plastic

tipped hammer and a piece of round steel stock, I tap-tap-tapped

every dent out of the flanges. The wood stand will help protect

the fittings while under restoration and future transportation,

bead blasting, and painting.

Continued...

Electronic

Ignition... Do it or don't.

Before I had

decided to start the rebuild, both engines were kinda working.

One friend (Dude) told me, "Electronic ignition! Yes!"

I liked the idea but I was unsure. I needed more information.

Another friend (Del) said "Electronic ignition will over

stress your old rings and you'll blow a hole or break

something!" I thought, "When in doubt, don't spend any

money!" And I didn't. (Good thing)

In the case of

this rebuild project, I say we go back in with E.I. I have done

all the home work and reading. I even instituted the pro's and

con's list of which I could not come up with any con's? Other

than the initial cost of installation.

On the pro side,

we have hotter spark. No points to go bad or replace. Continuous

faster and smoother starting means less wear and tear on the

starting system. It's newer, proven technology. I'm sure there's

more for it.

So it's shop

around time on the internet. See and get a feel for what's out

there and what the cost is. Most people want you to think of

adding more and special parts for more speed, more power. Adding

after market bolt on items to your engine is usually to boost

horse power or add rpm's. Well I don't want any part of that. I

already have 260 horses per side. What I want is to put this

thing back together as flat and as bullet proof stock as

possible. I don't want to have any finicky speed parts or add any

additional horse power that might over match the transmission and

out drives. I'm sure my new rebuilds will next to never be run

over 4,500 rpm.

Engine Heads:

Of the two heads I

pulled off #1 engine, none of the casting numbers matched 1969

and Jim at the shop didn't like the looks of either one of them.

The one spare head we found in the forward hold had 1968-70

casting numbers on it and must have been original equipment. It

looked as if it had been rebuilt and ready to go but I'll have to

send it in to the shop and have it checked and serviced before it

could ever be trusted. In the mean time I'll look for a

replacement head with the same cast numbers to match. I didn't

have to look long. Brian over at "Delta Propeller and Machine" had a matched set for sale. Seme casting numbers to

my surprise! All I was interested in were the cores. We settled on

$100 bucks if they magnafluxed ok and passed muster with Jim.

They did. So I got them and the rockers and rocker shafts as

well. Part of my master plan is to use the best two of the three

and finish the 3rd head to keep as a spare (Haven forbid). Don't

forget, I have a second engine to go yet.

Engine assembly:

The remainder of the

engine assembly lasted for the next several months. Great care was given to

assure a proper reassembly and fit for every part. Every thing that went back on

the engine was bead blasted, inspected, repaired, refinished, re-blasted and

painted. She sure looked pretty.

It

took a wile to finish all the electrical components and there connections. Once

upon a time thought I knew all the workings and logic of the internal combustion

engine but many years of not doing it caused a lot of my knowledge to laps away.

It’s a damn good thing I got a good buddy that seems to remember all the

things I forgot, and without him I’d have been sunk many time over! (Thanks

Deller!)

I

due course the reassembly was complete. What a buety! Boy she looked good

sitting there on the test bed ready and rearing to go. I should have, there and

then, hooked her up and tried to start her. But I didn’t.

I was a little scared I guess. Then I got sick. Then the family car got

sick. Then our vacation out of state came along. Then I was waiting for my

partner to come back from his vacation… Excuses. Excuses.

Start

your engine:

So

here we are, three months or so later. After all that my wife said “Come on,

get up! Get out there and start that beast!” I said… “There might be

flames!” “I might catch fire and blow up!” She said… “I promise I’ll

put you out if you catch fire!” “NOW GET OUT THERE AND DO IT!” “Come on,

I’ll help you. What do we do first?” (What a dear.) All that remained to be

done was to recheck all my wirework, prim the oil pump, hook up a remote

start/stop button and throttle. Everything else was set. Water feed, fuel pump

and sores.

We

were ready...

At

first there was a lot of turning over followed by nothing? Then a “Pow!”

(Backfire) “Hmm” Should have taken right off? Ok, on the phone to Deller.

“Did ya do this?” Yep. “Do that?” Yep. “Well try this and that and

call me back” ok… Before I was going to go long on anything I thought I

would review the firing order. Now some marine engines run in the reverse mode

for prop counter-rotation purposes. I know for a fact that both my engines are

“right hand rotation” hence on the engine information plate reads

“M-383-R” The “M” is for “marine.” Of course the 383 is the engine

size. The “R” is for “Right hand rotation.” My reverse rotation is

accomplished via transmition, not engine rotation. Upon the reevaluation of my

copy of the Chrysler marine manual, depicted there are diagrams of both

“right” and “left” hand sparkplug configurations. “Can you guess what

I did?” “Yep.” In short order I had all the sparkplug wires in there right

locations for the right hand engine rotation. Ok, here we go…”EVERYBODY

STAND BACK!!”…. Ignition on. Pump the throttle once for a drink of fuel and

(Hart pounding) turning the starter switch… My ears were reworded with the

rich wonderful sound of a big block Chrysler roaring to life! What a sound.

Music too my ears. It wasn’t as loud as I thought it would be but it was loud

enough. Man it sounded cool! The kids were jumping up and down, the dog was

barking, and my wife was clapping as best she could wile holding the “fire

blanket” and “fire extinguisher” she was going to put me out with should

things go wrong. (Good girl) The first run lasted about three minutes till the

small amount of fuel I used ran out. The ringing silence that followed was a

fond memory that will last indeed. It worked. It worked well. It didn’t run

then bust. Whack, or crunch. No bang or boom. No fires. No sparks. This was a

good thing for sure. All these fears of what might happen on start up were pent

up inside me all the way along the whole rebuild. All the money spent on parts

and machinening. All the long hours spent in the cold garage, truly not wasted

at all.

Of

course what was to follow was an emeadieat refueling, and at least three

separate “speakerphone calls” too Del, Barry and Carl demonstrating the

“Majesty and ausom roar” of a big block start up. (I had to share right?)

All call participants demonstrated proper levels of enthusiasm and

congratulations. Without these

great guys I could never have done it. (Thanks guys!)

Fine tune:

It

didn’t take too many days for Daryl to find his way to come visit and help me

do the final tweaking of carb and timing and such. By the time we finished with

it I’m sure the neighbors were done with it too. Although loud, the sound has

an alluring quality and drew in some of the local males as well as kids for a

better look-see. The engine was responding well indeed to our efforts. Temps

were good. (141) The carb rebuild held fast. No leaking of fuel of any kind and

all the linkages were working nice and smooth. We had a slight oil leak under

one valve cover. (No biggie, after the future re-touqueing of the heads I’m

going back with “Felpro cork” gaskets.) No other leaks, oil, coolant or

water were detected.

Over the course of the

next week or so I would start the engine now and then and get her up to temp.

Look for leaks, cracks, and /or flaws. None were found : ) A total of about five

gallons of fuel were ran through the engine and all seemed fine like wine. On to

the next step…

To

re-torque, or not to re-torque?

That

is the question...

I’m

talking about the engine heads after they have been installed on a rebuild.

I’ve heard arguments in all directions of how best to proceed. One guy told me

that if you re-torque ten minuets after the first time around that that’s good

enough. (I did that.) Another fella told me to run all the bolts down to spec,

then loosen them all up to finger tight. Then re-torque everything back down

again. He said that would be good enough and that re-torqueing later on would

not be nessery. (I didn’t do that.) The guys at the machine shop said that

would be bad due to the compression of the metal gasket. It should be compressed

only once. They also say the best

way is to re-torque after the engine has come up to temperature 3 or 4 times.

Just another good reason I had set up a test bed in the shop. (I did just that.)

Once I was satisfied with the run in and hose configuration and everything was

proved to work right. Then it was time to pull off the manifolds and valve

covers in order to give access to the bolts and re-torque the heads. I was glad

I did. The left bank had 7 or 8 bolts that turned a bit, but the right side had

only one that would turn. But still, all and all, to better maximize the life

expectancy and integrity of the heads, and there gaskets there of. I do believe

it’s well worth the extra effort to do it right and re-torque.

Prep

for transportation and re-insursion.

The

size and weight of the fully completed, ready to run “Chrysler M-383-R”

engine is huge. Not as huge as some, but It’s pretty darn big. Not just big,

but heavy. Like around 1500 lbs. When I de-installed it from the boat I did it

in pieces. You know, heads, manifolds, starter, pumps…the block was not to bad

to extract on it’s own. But put it all together and man! You got some heavy

stuff! How am I going to get it all back in? First of all I’ll leave all the

exhaust manifolds and all their apparatus off. That will shave a couple of

hundred pounds. No oil. No water. It’s still going to be heavy as hell. I

shutter to think of what would happen if some how it were to fall into the

bottom of the engine compartment! (Let’s not go there ok?) However for

safety’s sake we need to always keep that the bad sinareo in our minds in

order to proceed with a proper amount of safety and sanity.

And

no booze till after…

The old “in and out” routine.

I agonized for months and months over the

installation details and procedures for getting #1 engine back in its spot. Step

by step. Safely. Without incident. My friends think me anal to brood over every

little thing. There were so many preparations to do before I could put the

engine back in that I was a bit surprised when it finely came time to pick a

date to reinstall it. It was like “Well, here we are. Wow.” I’m not really sure why I came up with that next Sunday at

10: a.m. but it gave me some extra time for a buffer. I had to weld a counter

balance bracket for the picker, then test it in the grange at home first to be

sure of the proper load set up. All worked well, and everything seemed set. The

calls went out and manpower was arranged. On that next Friday morning the

weather reports were looking bad, and bad went to worse. Rain Sunday. (Damn) We

could see it on satellite moving in and looking long lived. I didn’t want to

push the date out. I was all set! Good to go. A week’s wait would be too

painful, so I made the call to bump. Yep! “Today’s the day.” I said.

Sun is out, and the tides are high. Winds are calm. Life is good. I made

the phone calls and the guys showed up by that afternoon. The new engine went in

slick as a whistle and the old #2 engine came out just as easy. The whole

operation lasted less than 2 hours and we were done well before dark. Backs were

slapped. Beers were served. Stories were told. Nobody got hurt. Nothing got

broke.

Anil my ass! Planning pays off…

A special thanks to my installation crew… Deller, Carl,

Kevin, and Randy.

Photos by Deborah

Mnw ; )

On to the next

page

River Queen Refit page.